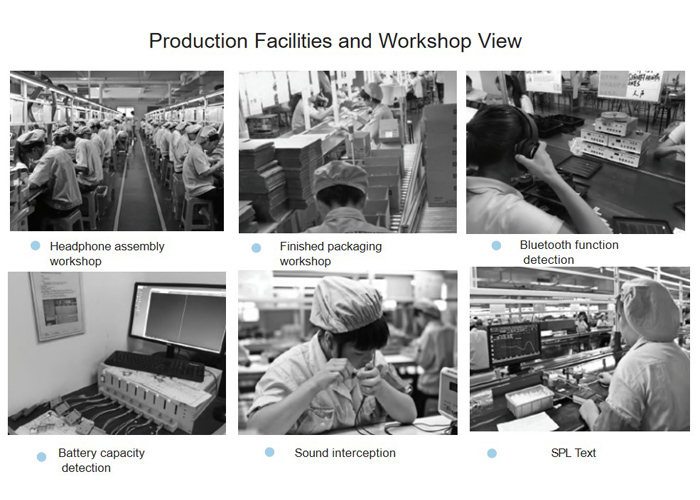

Production Facilities and Workshop View

Wire Pocessing

Semi-finished wire forming process:

1.Selection: Using environmentally friendly materials and adopted the followincJ test standards;

a.lnternal conductive materials to pass the pull test (3KG) standards;

b.Plastic materials to pass the temperature test - high temperature of 600C and the low temperature of -100C .

2.The molding process: To use the high-precision pressin g injection molding, and regularly random inspect the product in 10 minutes with micrometer, in order to achieve the consensus of product size.

3.Storage Inspection:According to AQL standards, FQC will random check for every 1000pcs of samples, to make sure the inspection is passed before storage.

4.Types of Processing: Earphone products are using round wire, flat wire, braided wire or double wire.

Finished wire Processing

Selection: Using environmentally friendIy materials and adopted the following test standards:

a.Using brass ring 6U material for diaphragm in order to enhance sound quality of speakers.

b.High standard of quality requirements. Using copper clad aluminum for voice coil processing and passed the life test of 72 hours.

c.Speakers passed the salt spray test of 48 hours.

Processing

a.Producing the semi-finished products by Automatic Magnetic Circuit Machines to make a better product consistency, and to avoid the damage of raw material caused by manual operation to order to reduce labor cost and manufacturing cost.

b.Assembly of finished products:To combine the processed magnetic and the membranes, and to assemble the finished-speakers.

c.Each speaker passed double inspections (audio test and frequency response test).

Metal Processing

1.Selection: Environmental friendly 6063 aluminum, all materials passed ROHS certification.

2.Processing

a.Metal ear cups using the "automatic lathe" or "CNC lathes " for molding processing,to process the aluminum into required shape.

b.Aluminum processing such as polishing, decontamination, grinding, washing tank, drilling, cleaning...etc to achieve the requirements of the next process to ensure the production quality for next process.

c.Plated color (Oxidation) during processing: Turning processing and pre-treatment of aluminum, sandblasted, fixtures, high temperature cleaning, oxidation of original color, oxidation color, high temperature oven, off-fixture, appearance checking, pac kaging...etc, Color processing for aluminum and each process are produced in accordance with the related technical standards and personnel management,to ensure that the consistency of oxidized color.

d.Will have carried knife, CD pattern, oil processing, screen printing, laser engraving...etc for aluminum with oxidized color. For those processed metal ear cups, QC will inspect the appearance with the relevant standards and then packaging and storage.

Assembly Processing

1. According to AQL standard, IQC will inspect the raw materials and semi-finished products for each batch. Storage after inspection passed. Production department will use the materials based on the product qualified mark to ensure the quality of materials;

2. According to the production schedule from PMC, a production line leader will get the materials and arrange materials for production on lines;

3. Before mass production, an approved Pre-production sample would be used as reference, and to ensure the production will run correctly and accurate;

4. Will inspect every earphone on production line with " audio instrument" and "curve tester".

5. During the assembly process, all the equipments are managed under the "Equipments Management Specification" in order to avoid hidden dangers;

6. For the finished products, IPQC will have random inspection in every 2 hours.

Packaging Processing

1. According to the production schedule from PMC, a production line leader will get the materials and arrange materials for production on lines.

2.Before mass production, an approved Pre-production sample would be used as reference, and to ensure the production will run correctly and accurate.

3.The assembled finished headphones in packaging production, again using the "audio tester" and "curve tester" performance and appearance inspection, so as to avoid glue drying process resulting in poor quality into the next process.

4.During the packaging processing, a staff would be assigned to inspect for any particular complicated process to avoid problems such as leakage of parts or raw materials which resulting in improper packing into the next process.

5.Before delivery, products with packaging will pass the vibration test for 12 hours,and high and low temperature test for 48 hours, to avoid age during transportation.

Latest News

Contact Us

Name: Marketing Department

E-mail: [email protected]

Add: Building 1,No.38,Longhe Road,Longgang District,Shenzhen,China.

Mail inquiry

Mail inquiry